Looth Group › All Forums All Topics › Quick Questions › Feeds and speeds for hardwoods

-

Feeds and speeds for hardwoods

Posted by Kat Creek on November 5, 2023 at 12:01 pmHi guys. I’m hoping someone has a good source for CNC machining feeds and speeds. I can find all the advice I want for aluminum etc, but I’m not easily finding this for woods. Thanks in advance. Kat

Paul M replied 1 year, 11 months ago 3 Members · 7 Replies -

7 Replies

-

For me it’s been a lot of trial and error. For the most part I run a 1/4″ flat mill at 100 in/min, but will oftentimes slow it down or speed it up based on my perception of how the cut is going. If I think the machine is working too hard I’ll stop the program and rerun it slower, if it’s dragging I’ll do the opposite.

Pretty clumsy but it works for me.

-

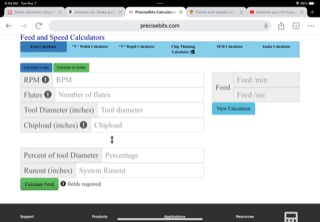

Thanks Paul. I’m relearning how to machine as I haven’t done this in five years. I’ve forgotten so much. I used to have a set speed like you do and alter it with the machine stress. I’ve found a calculator on precisebits.com that has inputs I’m not really familiar with like chip rate and runout, but I think I should learn what these mean. Again thanks for the input. It really helps.

-

I found a good resource for chip rates and speed rates for end mills of 1/8, 1/4, and 1/2″ diameters. They also have a speed rate calculator that includes hard woods. For a 1/4″ end mill running at 15,000 rpm, the speed rate is between 270 and 300 inches per minute. Seems very scary fast to me. I’ll try this on pine first!!! For an 1/8″ end mill the rate is between 90 and 150. The larger the tool the higher the speed rate. So the 100 inches per minute was a good guide value and just go slower for the end mills that are smaller than 1/8″.

https://cutter-shop.com/feeds-and-speeds-calculator/

cutter-shop.com

Speed and Feeds Calculator - CNC Tools - Cutter Shop

Use our free speeds and feeds calculator. It will give you information you need to calculate CNC router tool feed rates. Find out more.

-

A lot of this depends on your machine rigidity and your clamping. If you are taking a super shallow depth of cut that might work on any machine. But the chiprate calculations don’t take account of machine rigidity.

Basically the chip rate and speed calculations are the same whether you are taking a .1″ depth of cut or a 1″ depth of cut. It is a calculation on how much material the flute is cutting as it turns. . So it’s the same regardless. I’m not explaining it well but it’s true.

If your machine is rock solid you could push it that fast at 1″ and survive I think. But hobby machines are not that solid and I think more importantly if you are using blue tape or really any clamping other than a machinists vice you will probably blow the piece off the table. I have done that many times.

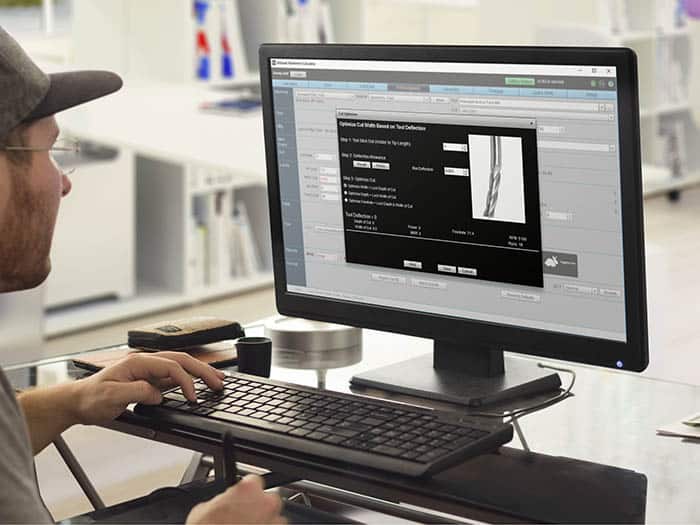

Many people understand this much better than I do. There’s a program that people use that I’ve heard is really helpful I’ll try to track down the name. It’s $70 but I’ve heard it’s a game changer.

-

Thanks for the information. I have a lot to learn as I am a self taught machinist. Yes if you can find an additional resource let me know. I’m not so much interested in going fast but machining a neck takes a long time at the speeds I used to use. I’m actually a bit timid…ok I’m really scared to go too fast!

My machine is being built at SegMag in Portugal. They are really solid. I’ll ask Joao the owner his opinion too on speed rates. I’m sure he will know a little 🙂 I was really fortunate to find a CNC manufacturer within 1 1/2 hours of my house. They even make their own control boards and have a company machine software that is an improvement to MACH3. It was a little more than I was expecting to pay. Yet experiencing using a kit machine was really painful and I wasted a lot of materials and time. I’ll be taking a video of my machine in process of being built and then the set up in my workshop. They are making a flip feature to allow for two sided machining without moving the blank off of the machine.

I’ll check out the Fusion teacher. Thanks again.

-

-

-

This is great! I was looking for something like this?

-

This is the program that was highly recommended. I haven’t actually used it but I might.

I think if you buy the cheaper version, you can use it for life if you don’t have a monster spindle.

https://www.cnccookbook.com/gwlitesignup-2/

Log in to reply.