We Are Unbelievably Sorry, But This Post Is For

Members

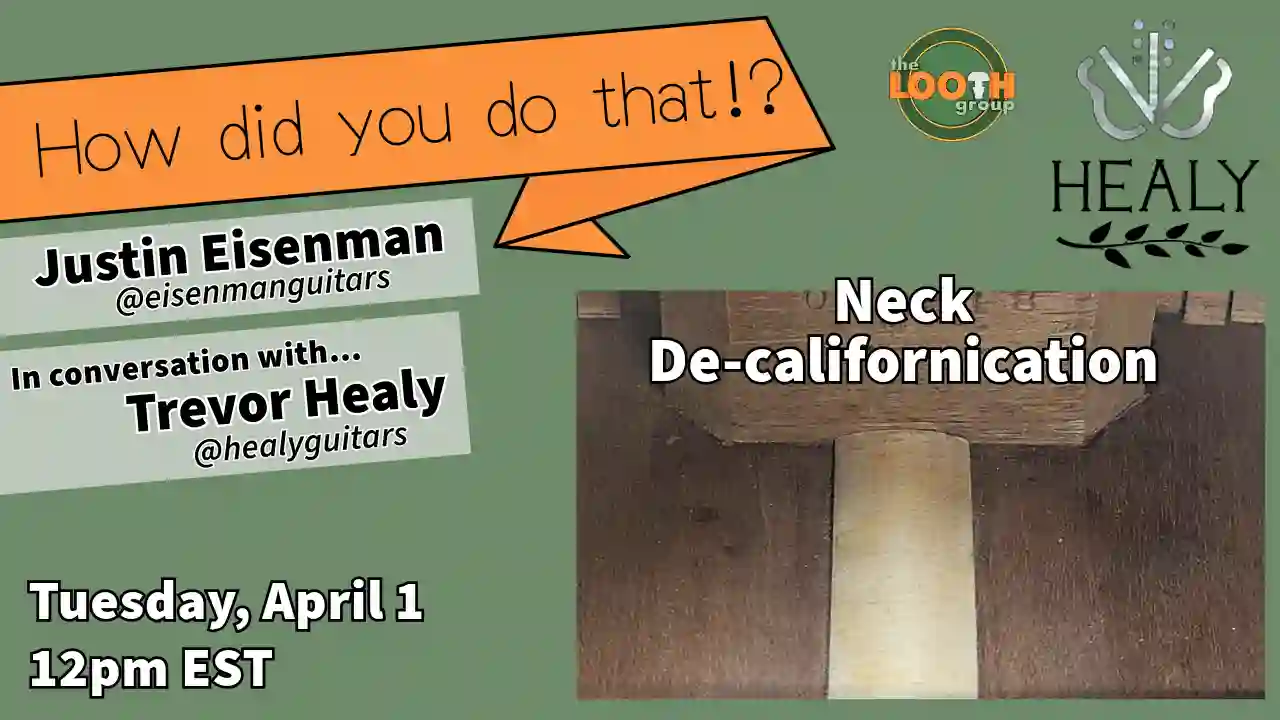

Want the full experience? Unlock all our premium content—including deep dives, exclusives, and more—by joining The Looth Group on Patreon.

If you have questions about membership, please email ian.davlin@gmail.com

00-21 Top Off Restoration

Related posts

Responses

Awesome job Ian! Also, the guitar pick shim is the stuff. I have so many of them that I hate…