We Are Unbelievably Sorry, But This Post Is For

Members

Want the full experience? Unlock all our premium content—including deep dives, exclusives, and more—by joining The Looth Group on Patreon.

If you have questions about membership, please email ian.davlin@gmail.com

Still thinking it over?

Subscribe to our weekly email for all the latest goings-on.

Files

extra_content_files_repeater does not have any rows

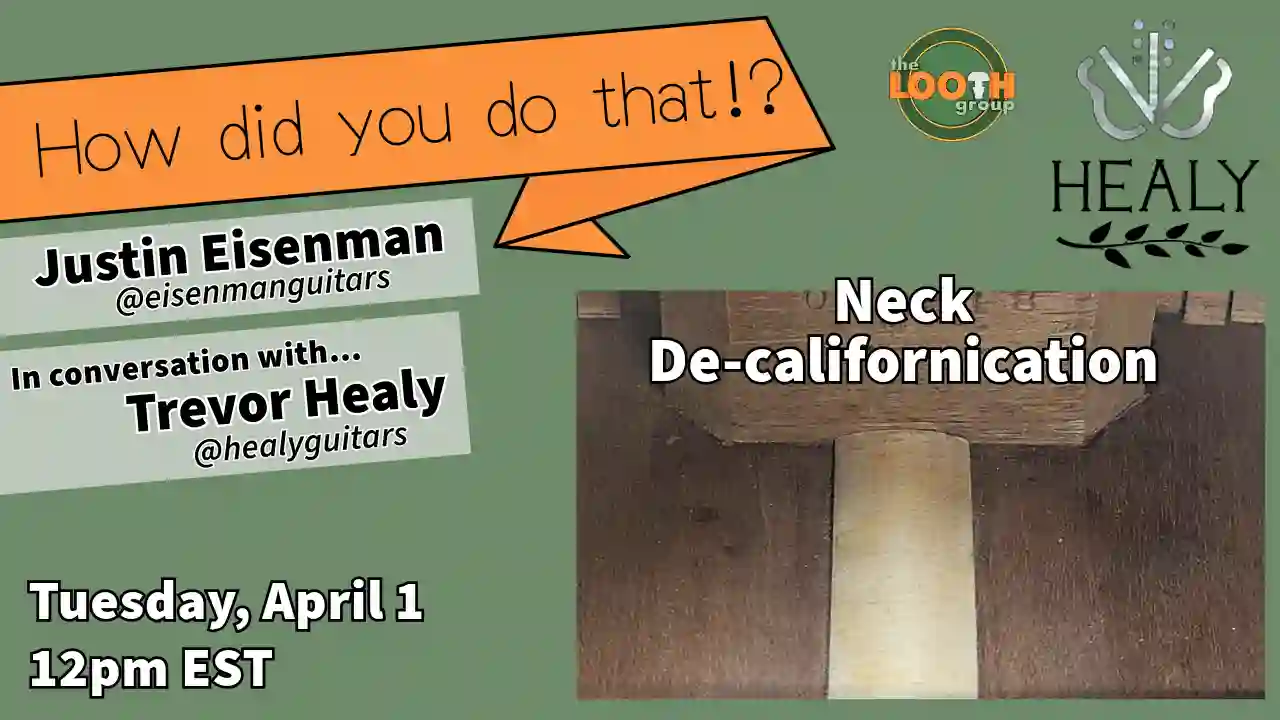

Neck Removal with Soldering Pencil Version 3

Related posts

Responses

That is hot !

And I Like the “Version 3” ’cause it is simply refining your idea, which Stewmac took further and refining using readily available items that any of us can pick up at the hardware store anywhere……..

Very elegant, simple and effective, as evidenced by your video. Thanks for sharing that!

That is brilliant Tony! Thanks for sharing this, you caught me before I ordered foam cutters. I’ve been using the heat stick, but was tired of the larger diameter hole it left. And I’m pretty sure I have an old iron sitting in a drawer somewhere.

love this video! This is so simple and I love that you tightened the copper wrap just like you would tying re-bar.

Yes! From back in the day when the old man had us kids tying for his foundations……..

An Addendum: You may notice that I add water to the holes. An that I use the dreaded “S” word……But that is not the intent! Yes, it is adding liquid to the “dry system” but this is my (probably fuzzy) reasoning. The water is to displace a poor conductor filling the voids (air) with a far superior conductor, CONDUCTION being the key. Water is FOUR TIMES MORE THERMALLY CONDUCTIVE then air. Think Hydronic heating (yes, they use Glycol but that’s to prevent freezing. Water is still a better conductor then Glycol). So I do put water in and fill to the top of the hole/s to fill in any voids around the copper wire and displace air in any voids, helping, I believe, to retain as much heat in the area as possible. This is a small amount of liquid and St#$m is, to my mind, a possible positive by-product of the real intention which is, once again, to obtain the most efficient CONDUCTIVITY we can get within this system. Of course the best liquid thermal conductor (and very dry at that) is……….Mercury 🪐 (couldn’t find a Mercury emoji)……….but I’m not using it……..